Wes Engines Services

[ezcol_1half]

Race engine development

4 Axis CNC machining

Engine Dyno Services

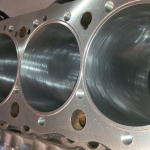

Block machining

Line boring

Cylinder honing

Digital crankshaft balancing

[/ezcol_1half]

[ezcol_1half_end]

Laser valve train testing

Cylinder head development and airflow testing

Cylinder head machining

Valve spring testing

Sonic and hardness testing

Crack testing

Race engine assembly

[/ezcol_1half_end]

Machine Shop Tour

[ezcol_1quarter] [/ezcol_1quarter]

[/ezcol_1quarter]

[ezcol_3quarter_end]

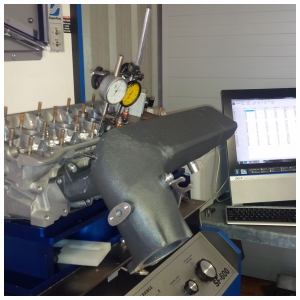

DYNO TUNING

Land & Sea computerised dynomometer[/ezcol_3quarter_end]

[ezcol_1quarter] [/ezcol_1quarter]

[/ezcol_1quarter]

[ezcol_3quarter_end]

LASER VALVE TRAIN TESTING

Our Spintek has the ability to test up to 11,000rpm

The laser valve tracking makes it possible to measure the following at any rpm:

Valve float

Valve bounce

Valve train deflection

Valve train component comparisons.[/ezcol_3quarter_end]

[ezcol_1quarter] [/ezcol_1quarter]

[/ezcol_1quarter]

[ezcol_3quarter_end]

AIRFLOW TESTING

Air flow development is a critical part of our engine program. The Superflow 600

with Flow Com linked to Performance Trends Port Flow Analyzer, gives us the

ability to overlay test after test. We can also test port velocity and report on

exhaust to inlet flow percentage.

[/ezcol_3quarter_end]

FADAL CNC MACHINE CENTRE

- 4 Axis Machining

- Surface Milling

- Cylinder Boring

- Block O-Ringing

- Cylinder Sleeving – Darton MID Sleeves

- Main Cap Conversions

- Cylinder Head and Intake Manifold O-Ringing

[ezcol_1quarter] [/ezcol_1quarter]

[/ezcol_1quarter]

[ezcol_3quarter_end]

SUNNEN CYLINDER HONE

CV 616 Cylinder Hone[/ezcol_3quarter_end]

[ezcol_1quarter] [/ezcol_1quarter]

[/ezcol_1quarter]

[ezcol_3quarter_end]

LINE BORING

The Berco BC5A line borer has the capacity to line bore blocks up to 2600mm

long and 850mm high. The Berco BC5A provides exceptional accuracy for

machining of:

main tunnels

cam tunnels (needle roller

conversions)

thrust faces

seal areas[/ezcol_3quarter_end]

[ezcol_1quarter] [/ezcol_1quarter]

[/ezcol_1quarter]

[ezcol_3quarter_end]

BALANCING

With the Turner digital balancer we can balance down to a 0 gram tolerance.

[/ezcol_3quarter_end]

[ezcol_1quarter] [/ezcol_1quarter]

[/ezcol_1quarter]

[ezcol_3quarter_end]

VALVE SEATING

The Serdi 1.1 achieves excellent levels of concentricity utilising the triple

workhead flotation system even in guide sizes as small as 0.118″/3mm. Multi

angle and radius set cuts are carried out on this machine.

[/ezcol_3quarter_end]

[ezcol_1quarter] [/ezcol_1quarter]

[/ezcol_1quarter]

[ezcol_3quarter_end]

ASSEMBLY ROOM

Once machining processes are finished and components are washed, the engines

are assembled in our dust free air-conditioned assembly room.

[/ezcol_3quarter_end]